360 EQUI-FLOW manages pressure and keeps NH3 liquid all the way to the injectors to ensure NH3 is distributed equally to every row, even in cooler temperatures, with far fewer losses and no crop damage. Better application means better use of ammonia and better-performing crops. And, a wider window of application, despite the temperature, means more flexibility for your operation.

360 EQUI-FLOW manages pressure and keeps NH3 liquid all the way to the injectors to ensure NH3 is distributed equally to every row, even in cooler temperatures, with far fewer losses and no crop damage. Better application means better use of ammonia and better-performing crops. And, a wider window of application, despite the temperature, means more flexibility for your operation.

Make the Most of Your Ammonia Investment

Vapor and cold flow anhydrous ammonia application systems rely on tank pressure for distribution and injection, which can cause them to unevenly deliver NH3 from row to row. That wide application variance causes streaking in the field and can rob you of yield. Traditional application systems also limit your NH3 application timing depending on the temperature, and freezing and build-up at the injection point hamper sealing. 360 EQUI-FLOW with Liquimatic Technology takes a new approach for better row-to-row accuracy and a wider window of application.

Key Features

- Precise row-to-row accuracy

- Wider window of application

- Keeps NH3 liquid all the way to the injectors

- Improved sealing at the injection point

Precision NH3 Application is Possible

Anhydrous ammonia is an economical and practical way to set a nitrogen foundation in the fall. But, conventional NH3 application systems limit your flexibility and your return on investment. 360 EQUI-FLOW ensures row-to-row accuracy so you can build an even, strong foundation for full-season nitrogen management.

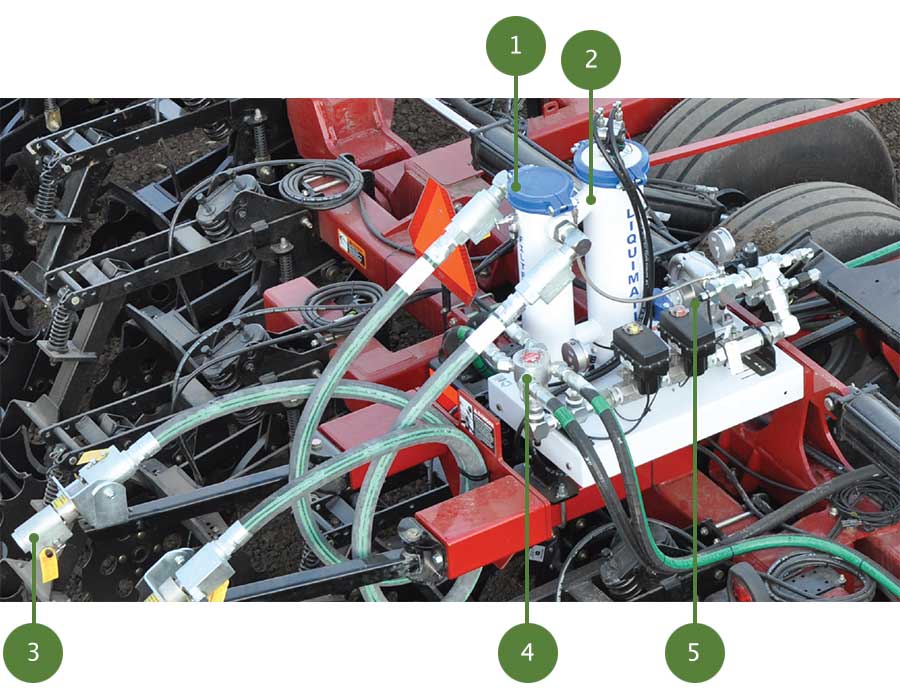

- Centrifugal pump boosts pressure for even application regardless of rate and temperature.

- Pre-assembled base unit works with any controller or monitor.

The ammonia is filtered at every step, right down to the orifice, so plugging virtually disappears and so does the danger posed by contacting the ammonia.

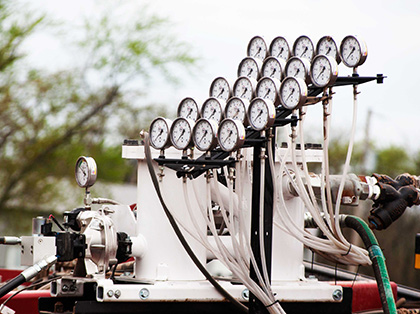

Only liquid NH3 passes through the flow meter. Since liquid measurement is more accurate than gas, you know exactly how much you are applying.

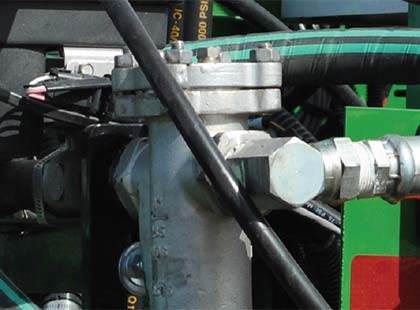

With the warm knife option – a vinyl tube insert – anhydrous never touches the knife or opener. So there's no frosting, no build-up, and no widening furrow. Sealing is improved and losses are minimized.

How 360 EQUI-FLOW Works

- Ammonia from the tank is delivered to the initial filter

- In the Liquimatic tower, the ammonia is separated into gas and liquid. The vapor is condensed back down into liquid and it all moves to the pump.

- Every row gets the same amount of ammonia in liquid state

- The equal distribution manifold equalizes flow to each outlet.

- The hydraulically driven centrifugal pump pushes 100% liquid ammonia through the flow meter and control valve to the manifold.